Vinyl Chloride Monomer (VCM) Production

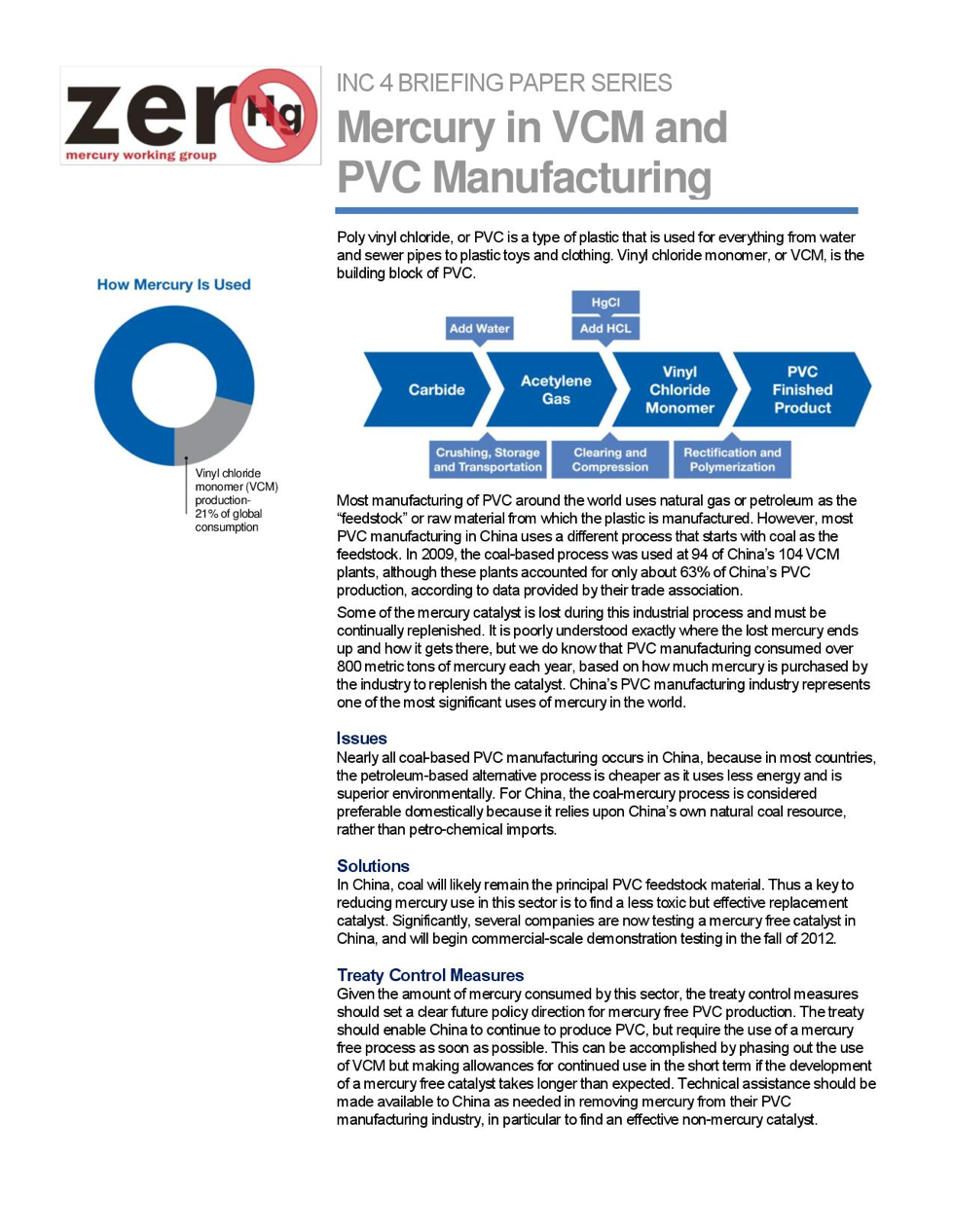

Poly vinyl chloride, or PVC is a type of plastic that is used for everything from water and sewer pipes to plastic toys and clothing. Vinyl chloride monomer, or VCM, is the building block of PVC.

Most manufacturing of PVC around the world uses natural gas or petroleum as the “feedstock” or raw material from which the plastic is manufactured. However, most PVC manufacturing in China uses a different process that starts with coal as the feedstock.

In that coal-based process, mercury is a catalyst to spark the chemical reaction among ingredients. In 2009, the coal-based process was used at 94 of 104 China’s VCM plants, although these plants accounted for only about 63% of China’s PVC production, according to the latest data provided by their trade association.

Some of the mercury catalyst is lost during this industrial process and must be continually replenished. It is poorly understood exactly where the lost mercury ends up and how it gets there, but we do know that PVC manufacturing consumes over 800 metric tons of mercury each year, based on how much mercury is purchased by the industry to replenish the catalyst. China’s PVC manufacturing industry represents one of the most significant uses of mercury in the world today.

Nearly all coal-based PVC manufacturing occurs in China, because the petroleum based alternative process uses less energy, is cheaper in most countries, and superior environmentally. For China, the coal-mercury process is considered preferable domestically because it relies upon China’s own natural coal resource, rather than petrochemical imports. There are also practical barriers against using the petroleum-based process in the interior (non-coastal) regions of China, where much of the PVC production capacity exists or is planned.

In China, coal will likely remain the principal PVC feedstock material. Thus, a key to reducing mercury use in this sector is to find a less toxic but effective replacement catalyst. Significantly, several companies have plans for early 2011 to pilot test a mercury free catalyst in China, and commercial demonstration testing could soon follow.

Relevant legislation and NGO policy work

Globally

The Minamata Convention on Mercury, under Article 5 requires that Each Party shall take measures to restrict the use of mercury or mercury compounds in the processes listed in Part II or Annex B in accordance with the provisions set out therein. For the Vinyl chloride monomer production using mercury containing catalysts the provisions include:

- Measures to be taken by the Parties shall include but not be limited to.

- Reduce the use of mercury in terms of per unit production by 50 per cent by the year 2020 against 2010 use;

- Promoting measures to reduce the reliance on mercury from primary mining;

- Taking measures to reduce emissions and releases of mercury to the environment;

- Supporting research and development in respect of mercury-free catalysts and processes;

- Not allowing the use of mercury five years after the Conference of the Parties has established that mercury-free catalysts based on existing processes have become technically and economically feasible;

- Reporting to the Conference of the Parties on its efforts to develop and/or identify alternatives and phase out mercury use in accordance with Article 21.

The ZMWG has been following this issue closely and has been giving respective feedback at the global mercury negotiations. See also the ZMWG fact sheet on VCM (Jan 2011)

In the EU

The revised Regulation (EU) 2017/852 on mercury prohibits the use of mercury or mercury compounds, whether in pure form or in mixtures, in the production of vinyl chloride monomer from 1 January 2022.