Cement production

The raw materials such as lime, coal and oil that are used for cement production usually contain trace concentrations of mercury. In addition, solid residues from other sectors such as fly ash and gypsum often used as raw materials for cement production contain mercury as well. Also the waste that is sometimes used as fuel in cement manufacturing may significantly increase the total input of mercury to cement production.

Sometimes the use of materials with low concentrations of mercury could lead to significantly high releases of mercury into the atmosphere if the consumption of these materials is in very large quantities.

Emissions from cement production amount to 9.8% of the global mercury emissions to air.

Relevant legislation and NGO policy work

Globally

The Minamata Convention on Mercury, Article 8 concerns controlling and where feasible, reducing emissions of mercury and mercury compounds, to the atmosphere though measures to control emissions from certain point sources (Annex D) including cement clinker production. Different measures are requested for existing and new installations.

Furthermore Guidance on Best Available Techniques and Best environmental practices in relation to emissions from point sources under Annex D of the Minamata conventionhas been finalised at UNEP level and should be considered.

Work has also been done under the UNEP Global Mercury Partnership on Mercury releases from the cement industry

In the EU

In 2010- the Integrated Pollution Prevention and Control (IPPC) Directive (96/61/EC) was replaced by the Industrial Emissions Directive (IED),which has entered into force on 6 January 2011 and wastransposed into national legislation by Member States by 7 January 2013. Although the principle is the same as for IPPC, the role of the Best Available Technique (BAT) Reference Documents (BREFs) has been strengthened, providing more opportunities to the legislator to question why mercury process may still be permitted in the sector.

After a BREF is completed, it should be subject to BAT conclusions that are adopted through a comitology decision (implementing act). The right of initiative however rests with the Commission. BAT conclusions contain parts of the BREF, their description, information on applicability, including BAT Associated Emission Levels (BATAELs) for different pollutants (meaning emission levels that can be achieved for a pollutant if the industry is implementing BAT) as well as associated consumption levels and monitoring. It may also include site remediation measures “where appropriate”. Within 4 years after publication of the comitology decision on the relevant BAT conclusions, local authorities should review and update all the permits to the respective industries in order to make sure the industrial activity operates according to the requirements set out in the BAT conclusions. The provision in the IED requires that Emission Limit Values (ELVs) for pollutants set out in the permit should not exceed the relevant BATAEL. However the permit writer may derogate in specific cases and set higher ELVs under certain conditions. An assessment needs to demonstrate that the application of the BATAEL would lead to disproportionate higher costs compared to the benefits due to the local conditions (technical characteristics of the plants, or geographical location or local environmental conditions). In any case no significant pollution may be caused and a high level of protection of the environment as a whole is achieved. Environmental Quality Standards also need to be respected. These derogations are subject to public participation and scrutiny by the public concerned, which includes NGOs.

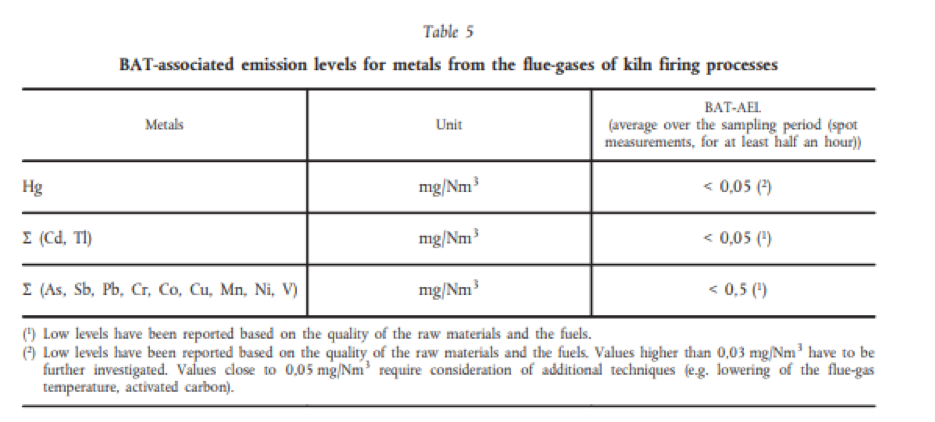

The benchmarks or criteria on which BAT relies are described in the BAT Reference Documents (BREFs). The Cement, Lime and Magnesium Oxide Manufacturing Industries BREF document and its respective BAT Conclusions were adopted in March 2013. With respect to mercury emissions the BAT conclusions are layed out below: